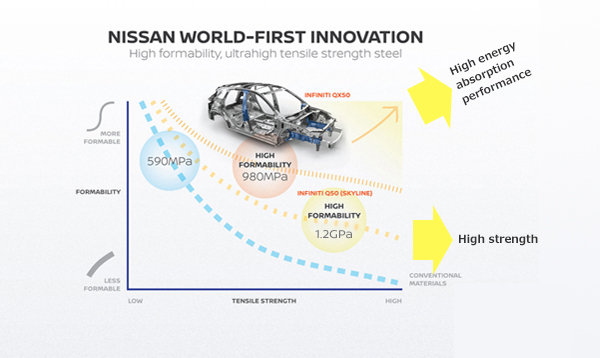

Ultra High Tensile Strength Steel with High Formability

This material achieves both high strength and elongation capacity while also reducing vehicle body structure weight

Vehicle

weight

and

size

have

been

increasing

in

recent

years

with

the

pursuit

of

safety

and

comfort.

Weight

reduction

is

an

unavoidable

path

for

auto

manufacturers,

in

order

to

improve

fuel

consumption

and

reduce

CO2

emissions.

Nissan

has

dedicated

itself

to

developing

new

materials

to

reduce

a

vehicle’s

overall

weight.

In

order

to

simultaneously

clear

the

two

issues

of

“reducing

vehicle

weight

to

reduce

environmental

impact”

and

“improving

collision

safety”,

Nissan

has

focused

on

using

high

tensile

strength

steel

in

their

vehicle

body

structures.

The

results

are

body

structures

that

are

not

only

strong

but

also

highly

formable.

In

2013,

Nissan

succeeded

in

developing

a

1.2

Gpa

ultra

high

tensile

strength,

high-formability

steel

that

was

stronger

than

conventional

high

tensile

steels.

This

new

material

was

first

used

in

the

Infiniti

Q50

midsize

sedan.

In

2018,

Nissan

developed

and

introduced

a

980

MPa

ultra

high

tensile

strength,

high-formability

steel

that

featured

further

improvements

to

collision

energy

absorption

performance.

This

material

was

used

in

the

Infiniti

QX50

premium

midsize

SUV.

Research

and

development

efforts

such

as

Ultra

High

Tensile

Strength

Steel

have

resulted

in

further

reducing

vehicle

weight

and

improving

collision

safety.

System operation

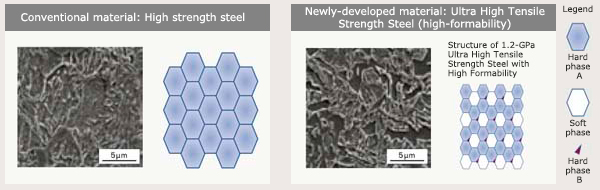

- As a general rule, when the strength of high tensile steel is increased, its elongation capacity decreases. A decrease in elongation capacity can cause cracking during cold-press forming. Because prior high tensile strength steels were unable to withstand cold-pressing into complex shapes, they were used only for a limited number of parts.

- The advantage of 1.2-GPa Ultra High Tensile Strength Steel with High Formability is to have both high strength and elongation capacity. By precisely controlling the material’s structure on the sub-micron level through a new heat treatment process, it can be utilized for many more body structure parts than previously possible.

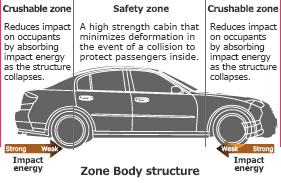

- A spot welding method suitable for 1.2-GPa Ultra High Tensile Strength Steel with Formability has also been developed. The new welding method makes it possible to use this steel for “Safety Zone” structure parts, such as the center pillar reinforcement, front roof rails, and side roof rails, meant to protect vehicle occupants in the event of a collision.

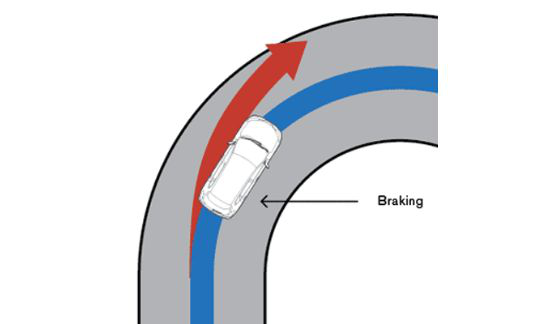

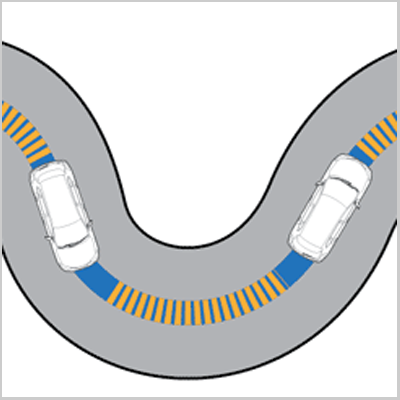

- For the newly developed 980-MPa Ultra High Tensile Strength Steel with High Formability, a more finely tuned heat treatment process that gives the material high energy absorption performance was achieved. As a world-first, Nissan began using this material on the front side members, rear side members, and other “crushable zone” frame parts that require high collision energy absorption. This material has the same level of formability as conventional 590-MPa steel, and can be used for parts with more complex shapes.

Nissan has established a target of using Ultra High Tensile Strength Steel with High Formability in 25% or more of the gross weight of body parts. Nissan is actively moving forward with the development of technologies for applications of high strength steel and expands its use in the Nissan model line-up.