e-POWER's internal combustion engine achieves 50% thermal efficiency

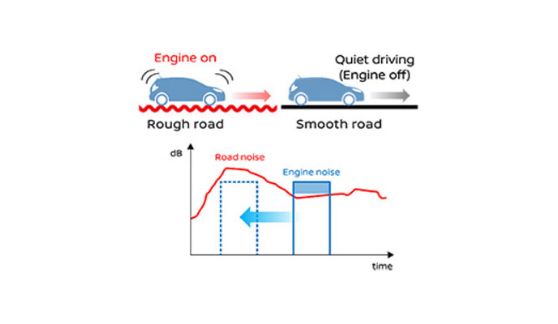

Efficient, fixed-point operation is achieved by restricting the engine's operating range, which is only possible for an engine that is dedicated to electricity generation

Improving

engine

efficiency

is

an

issue

that

is

common

to

automobile

manufacturers,

and

a

maximum

of

approx.

40%

thermal

efficiency*1

is

being

achieved.

However,

it

took

almost

30

years

to

improve

thermal

efficiency

from

30%

to

40%.

With

e-POWER,

Nissan

specializes

the

role

of

the

engine

for

electricity

generation,

and,

furthermore,

achieves

a

thermal

efficiency

of

50%

through

lean

combustion*2

based

on

the

unique

STARC*3

concept

and

waste

heat

recovery

technology.

This

makes

it

possible

to

further

improve

fuel

efficiency

and

to

reduce

CO2.

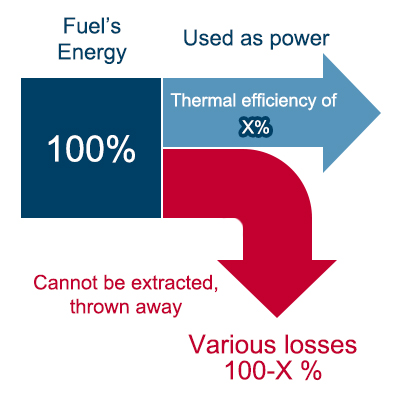

- Thermal Efficiency: Ratio of the fuel's energy that can be extracted as power

- Lean Combustion: Combustion with an air-fuel mixture ratio that has more air than the theoretical air-fuel ratio (wherein the fuel and oxygen reaction have perfect proportions; that is, the ratio of completely burned air to fuel). Lean combustion with an excess air ratio of λ = 2 is assumed.

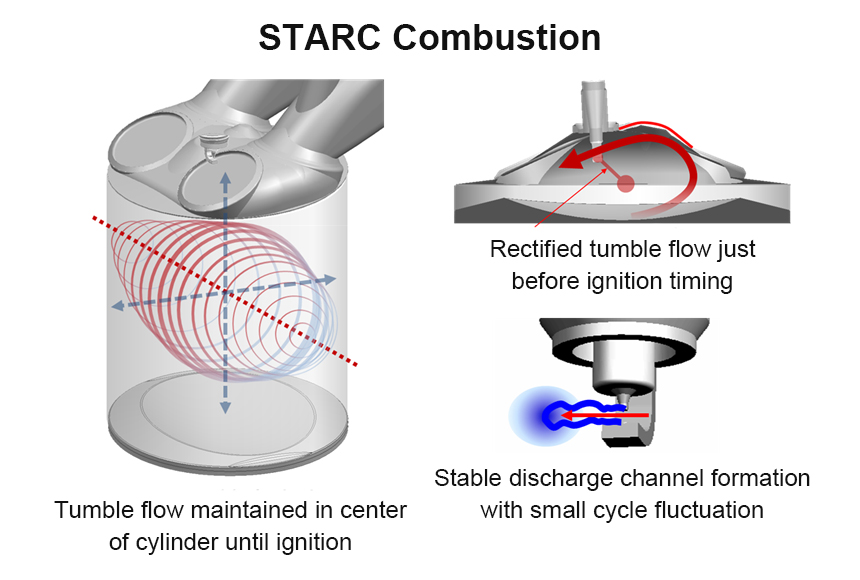

- STARC: Strong Tumble & Appropriately stretched Robust ignition Channel

System Mechanism

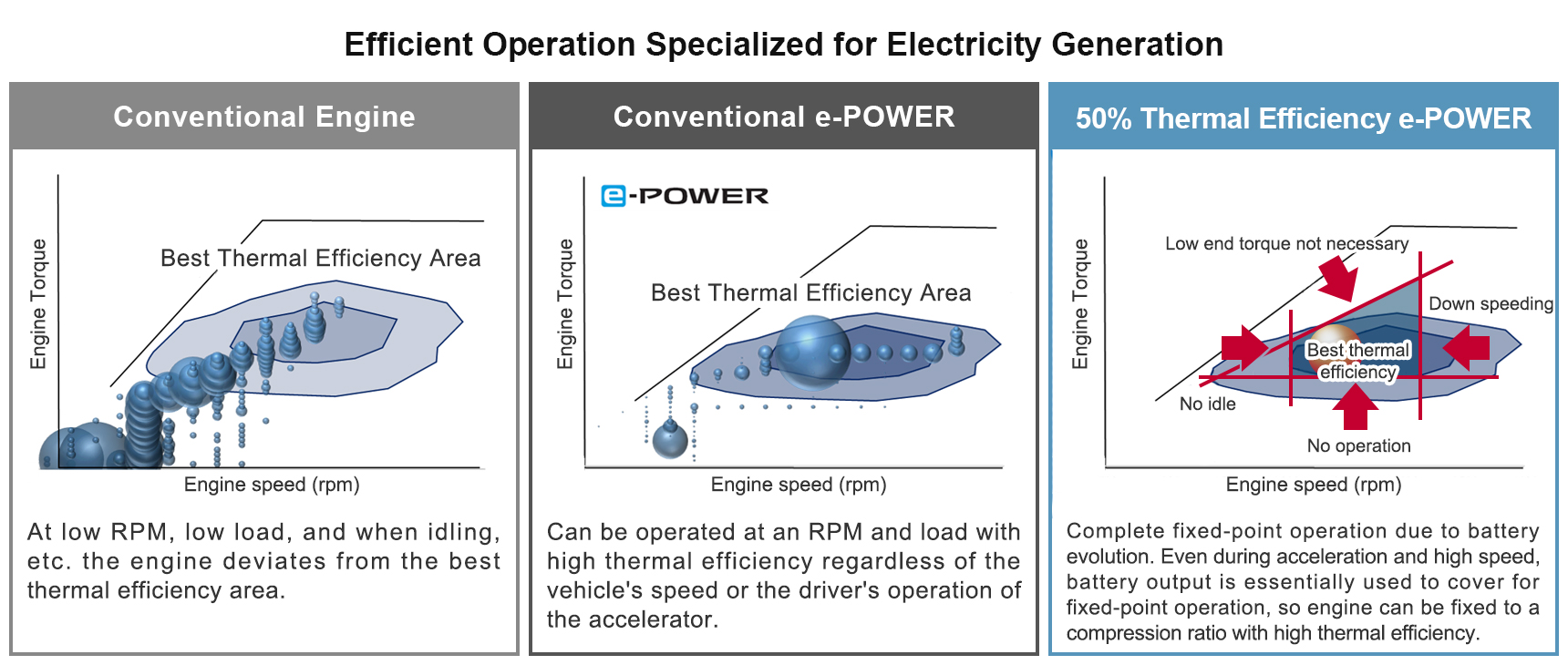

By specializing the engine for electricity generation, it can be operated in its most efficient range. Furthermore, Nissan will continue to develop its battery technology to achieve fixed-point driving to achieve the most efficient driving possible. Through this, fuel economy can be improved.

Based on the unique STARC concept, the intake manifold, combustion chamber, and piston shape are optimized for the fixed-point operating range of the electricity generation engine and form a stable and extended spark plug discharge channel*4 by maintaining a strong tumble flow in the center of the cylinder. This enables stable combustion under highly diluted conditions, such as high EGR*5 and lean combustion, and improves thermal efficiency.

- Discharge Channel: The flow of electricity through the air discharged for ignition.

- EGR (Exhaust Gas Recirculation): Technology that recirculates a portion of the exhaust gases after combustion, intaking them again. Although combustion of the air-fuel mixture diluted via EGR improves thermal efficiency, ensuring combustion is a challenge.

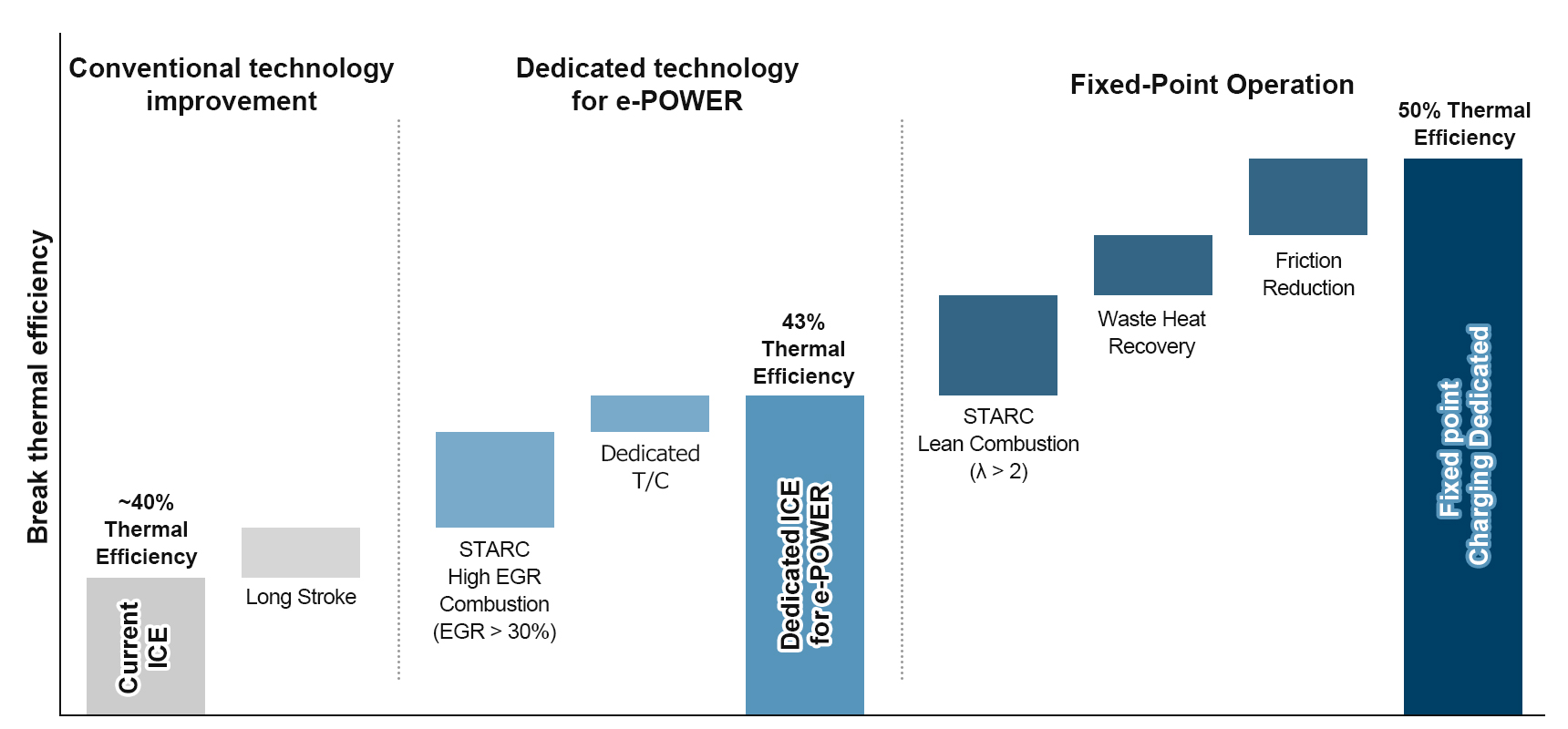

Measures to Achieve 50% Thermal Efficiency

For

conventional

engine

technologies,

basic

thermal

efficiency

was

improved

by

lengthening

the

stroke

and

reducing

friction.

Furthermore,

by

restricting

the

engine's

operating

range

utilize

e-POWER,

it

is

possible

to

improve

the

theoretical

thermal

efficiency

using

high

EGR

combustion

under

the

STARC

concept,

reducing

intake

and

exhaust

losses

via

the

dedicated

turbo,

achieving

a

net

thermal

efficiency

of

43%.

Additionally,

due

to

the

evolution

of

battery

technologies

in

the

future,

through

the

shift

to

fixed-point

operation,

the

engine

will

achieve

50%

thermal

efficiency

through

lean

combustion

based

on

the

STARC

concept,

even

further

reductions

in

friction,

and

efficient

recovery

of

waste

heat.